For the dynamic world of production and layout, the capability to transform basic materials into elaborate and practical types is vital. Amongst the diverse range of shaping methods readily available, Vacuum cleaner Forming attracts attention as a functional, affordable, and effective method for creating a vast range of plastic items. From the protective packaging that supports our goods to the durable components discovered in vehicles and appliances, the impact of Vacuum cleaner Forming services is pervasive, usually undetected yet undeniably crucial.

At its core, Vacuum Forming is a procedure that uses warm and vacuum stress to mold and mildew polycarbonate sheets right into wanted forms. The magic begins with heating a sheet of plastic up until it comes to be pliable. This softened sheet is after that draped over a mold and mildew, which can be crafted from different materials like wood, light weight aluminum, and even resin, relying on the manufacturing quantity and intricacy of the part. As soon as in position, a vacuum cleaner is applied below the sheet, drawing the softened plastic firmly against the contours of the mold. As the plastic cools down, it keeps the form dictated by the mold and mildew, resulting in a precisely created component.

The appeal of Vacuum cleaner Forming lies in its adaptability. It can suit a wide range of thermoplastic materials, each offering distinct properties in terms of stamina, adaptability, chemical resistance, and visual charm. Common products used in Vacuum cleaner Forming services consist of ABS, PVC, acrylic, polycarbonate, and PETG, to name a few. This adaptability enables producers to choose the perfect product to satisfy the certain demands of their application, whether it's the effect resistance needed for automobile components or the quality needed for retail packaging.

The applications of Vacuum Forming services are remarkably varied, covering many sectors. In the packaging industry, Vacuum cleaner Forming contributes in creating blister packs, clamshell packaging, and trays that shield and display items. The vehicle industry relies on Vacuum cleaner Forming for making interior components like dashboards, door panels, and seat backs, in addition to outside components such as fender liners and light real estates. Device producers make use of Vacuum cleaner Forming to generate fridge liners, control board, and various housings. Also the medical area gain from Vacuum Forming in the creation of medical trays, equipment real estates, and prosthetic parts.

Past these core applications, Vacuum Forming services are likewise used in the production of signage, point-of-sale displays, agricultural components, and even recreational tools. The capacity to produce complicated shapes with family member simplicity and at a reduced tooling expense contrasted to processes like injection molding makes Vacuum cleaner Developing an appealing choice for both large-scale production runs and smaller sized, much more specialized jobs.

Choosing the best Vacuum cleaner Forming service provider is vital for ensuring the high quality, precision, and cost-effectiveness of your task. Experienced Vacuum cleaner Creating companies possess the proficiency to lead you with the entire procedure, from product selection and mold design to production and finishing. They can offer important understandings right into enhancing your style for the Vacuum cleaner Forming procedure, making sure reliable manufacturing and minimizing product waste.

Additionally, trusted Vacuum Forming services typically provide a series of additional operations to enhance the end product. These can consist of trimming, die-cutting, CNC directing, painting, and assembly, offering a extensive solution from resources Vacuum Forming to end up part. This incorporated strategy can improve the manufacturing process and reduce lead times.

Finally, Vacuum Forming solutions represent a effective and functional production strategy that plays a important role fit the products we make use of on a daily basis. Its flexibility to various products, its cost-effectiveness for a range of manufacturing quantities, and its capability to produce complicated geometries make it an important device throughout various industries. As design technology continues to push the limits of what's possible, the need for top quality Vacuum Forming services will most certainly continue to grow, strengthening its setting as a keystone of contemporary manufacturing. Whether you require safety packaging, durable commercial parts, or visually enticing display screens, exploring the opportunities supplied by expert Vacuum Forming solutions can unlock a globe of forming capacity for your following project.

Anna Chlumsky Then & Now!

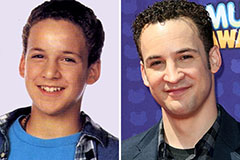

Anna Chlumsky Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Morgan Fairchild Then & Now!

Morgan Fairchild Then & Now!